1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic Flow/Deformation Simulation)

5. MasterCAM (CNC Programming)

6. Unigraphics (CNC Programming)

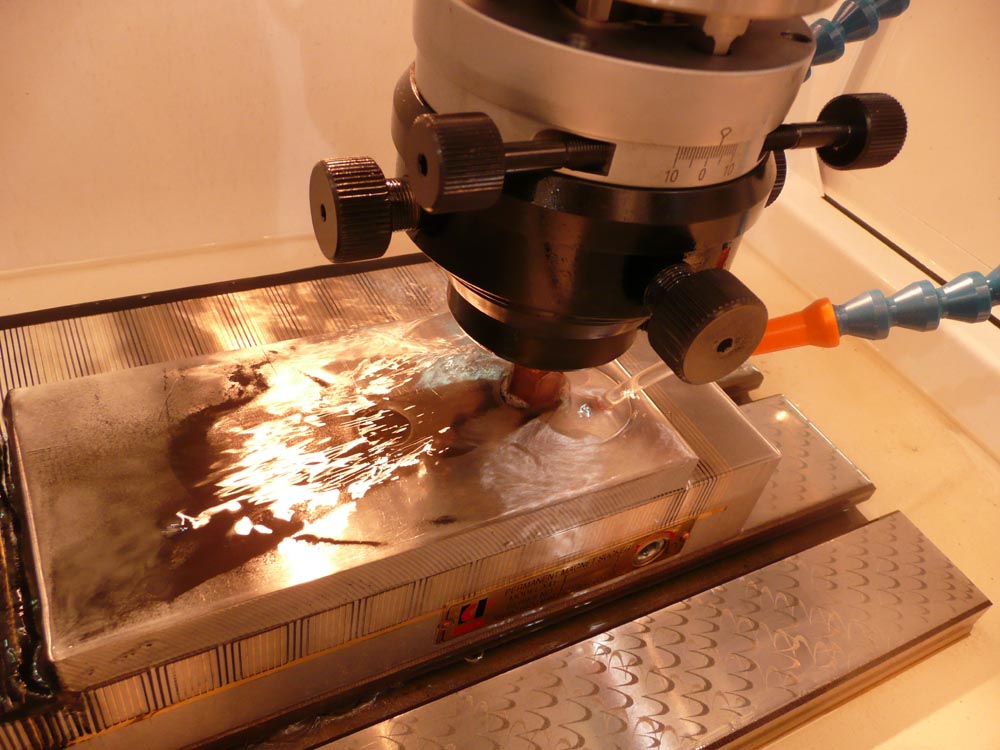

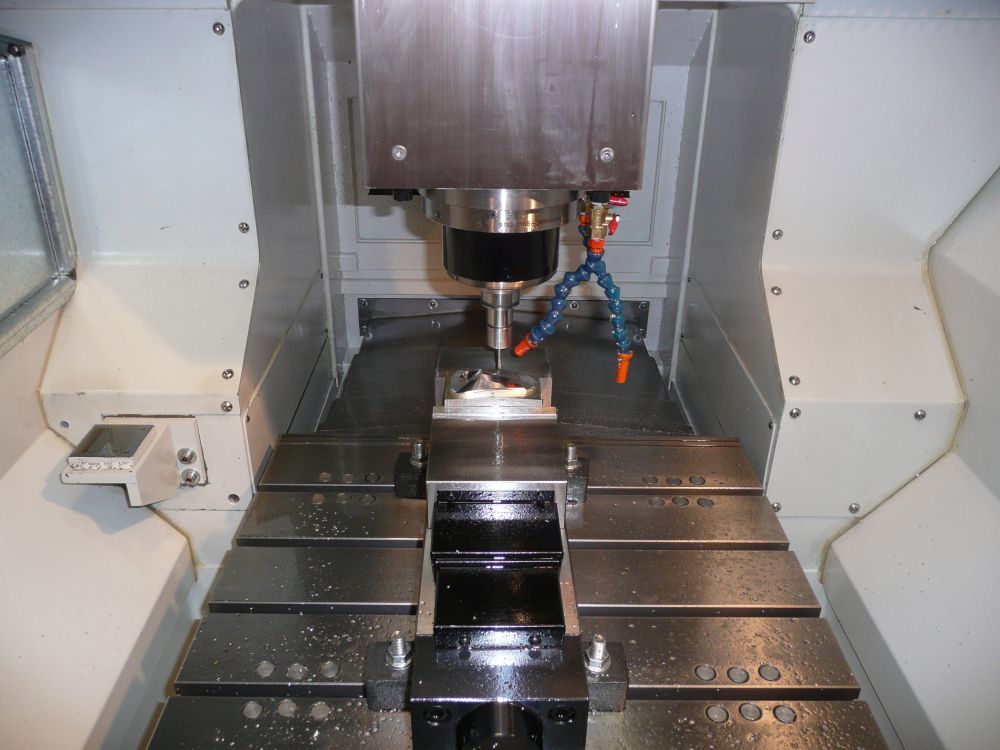

7. CNC Machining Centers

8. CNC EDM's (Electrical Discharge Machining)

9. Wire Cutting Machines

We have many years of experience in producing plastic molds. From mold design to mold testing, we provide a complete in-house service, making us your preferred choice for plastic mold manufacturers in China. Managed by professional staff with comprehensive technical skills and years of experience, we have many top-notch equipment such as CNC, EDM, engraving machines, wire cutting machines, etc. We use the latest CAD/CAE/CAM, which not only ensures mold quality but also improves efficiency.

Zhongda, with an open and enterprising spirit, maintains extensive connections with experts and customers in the field. Researching, learning, and cooperating to invigorate the industry.

(1) Vernier Calipers, Micrometers, Thickness Gauges, Thread Gauges.

(2) Hardness Testers, Temperature Measurement Instruments, and Color Charts.

(3) Toolmaker's Microscope, Surface Plates.

(4) Coordinate Measuring Machines.

Before delivering products to our customers, each of us must go through the relevant quality inspection processes to achieve perfect standards.